Przejdź do akapitu:

Surface preparation

Seasoning of plasters

Seasoning

New cement and lime plasters can be smoothened after 3-4 weeks, gypsum plasters after 2-3 weeks – it’s necessary time so that the plaster can bind as well as all chemical reactions can take place. Poor surfaces must be primed with ACRYL-PUTZ® Grunt Polimerowy Głęboko Penetrujący or ACRYL-PUTZ® Grunt Polimerowy Uniwersalny depending on the surface absorptiveness degree. If it’s necessary to enhance adhesive properties one should use ACRYL PUTZ® Grunt Polimerowy Kontakt. Before application the surface must not be moistened but dedusted.

Surface priming

Preparation of renovated surface

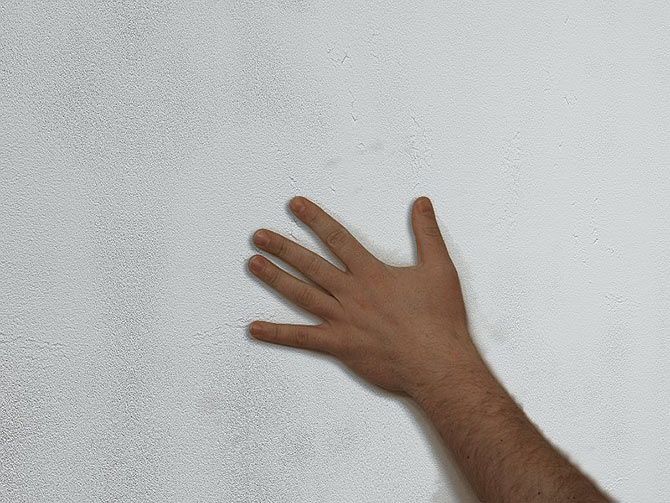

Testing the adhesive properties of the surface

Testing the surface by rubbing with a palm

In the event of smoothening the walls with old painting coatings, the surface must be prepared properly. Precise test of adhesive properties of the surface is a very important activity as far as proper adhesiveness of further applied putties is concerned. If the renovated surface is too chalky i.e. leaves palm chalking after rubbing, it’s necessary to prime it with ACRYL-PUTZ® Polimerowym Głęboko Penetrującym or Gruntem Polimerowym Uniwersalnym depending on the absorptive properties of the surface. Before application the surface must not be moistened but dedusted.

Testing the adhesive properties of old coatings

Cutting up lines

Removing the painting tape from the surface

In order to test adhesiveness of old coatings to the surface it’s recommended to carry out a spot test. To conduct the test one should cut up slight vertical and horizontal lines. The distance between the lines should be between 4 and 4 mm. Next it’s necessary to stick the tape upon the cut surface and after a while remove it vigorously. If the tested coating comes off of the surface it’s necessary to remove it and prepare the surface.

Removing old coatings

Removing old coatings with the use of putty knives

Before priming it’s necessary to remove old loose painting coatings by using a metal putty knife.

Priming

Surface priming

In order to uniform the absorptive properties of the surface as well as strengthen it and enhance adhesive properties of putties, it’s necessary to strengthen the poor surface by applying the following primers ACRYL-PUTZ® Polimerowym Głęboko Penetrującym orACRYL-PUTZ® Grunt Polimerowy Uniwersalny depending on the absorptive properties of the surface. Before application the surface must not be moistened but dedusted. The primer prevents from absorbing the water to the surface. It provides proper drying conditions for surface products as well as makes the coatings permeable for vapours and gases.

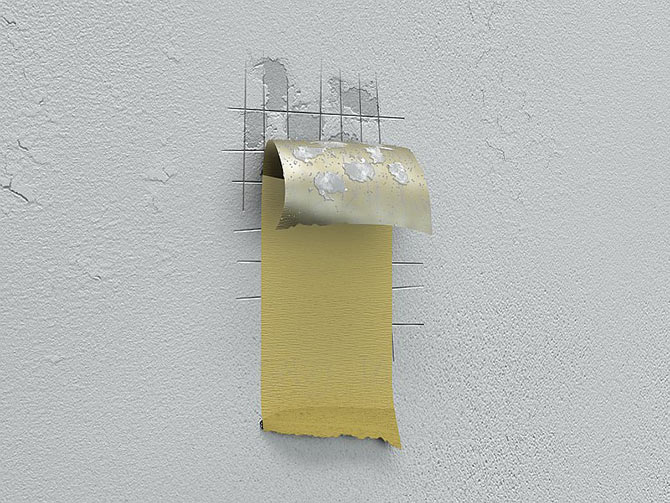

Removing cracks and defects

Applying ACRYL-PUTZ® FLEX upon cracks

To remove cracks and defects of width to 5mm it’s recommended to apply an elastic putty mass ACRYL-PUTZ® FLEX which – thanks to the content of glass fibres – prevents effectively from creating new cracks.

Before removing cracks and defects it’s necessary to deepen them by using a tool with a sharp edge e.g. a putty knife and then clean the spot. Further stage is to apply ACRYL-PUTZ® FLEX.

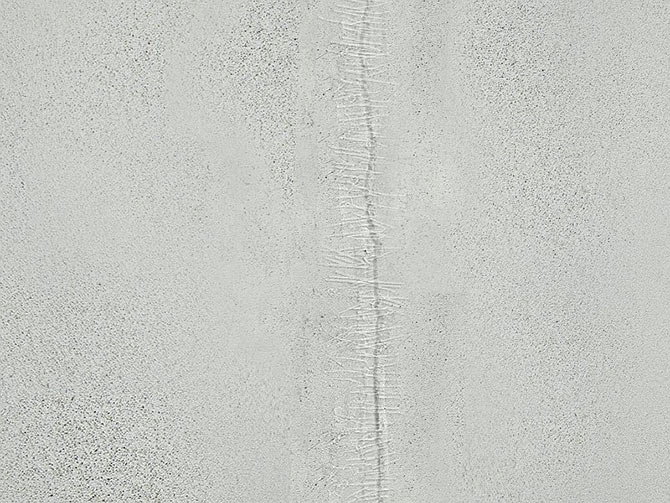

Cracks fixed by ACRYL-PUTZ® FLEX – transparent layer

The putty mass after drying leaves a transparent layer with visible glass fibres which can be covered with the following putties ACRYL-PUTZ® START, FINISZ or FASADA

Removing serious defects

Removing serious defects – cracks

Before applying the levelling layer it’s necessary to remove bigger cracks by using ACRYL-PUTZ® START. One layer can amount even to 3 cm – in single cracks

Assembly of corner sections

Assembly of aluminium sections to the wall corner

It’s recommended to safeguard spots particularly exposed to rubbing e.g. wall corners in corridors, staircases or door areas, by using aluminium sections. Assembly of the sections must be commenced by spot applying putty mass ACRYL-PUTZ® START and next press against the corner the proper aluminium section in precise vertical or horizontal position.

After about 30 minutes the aluminium section must be covered in the putty. After drying the whole spot must be covered with another layer of the putty.

Smoothening – levelling layer

An ideal product to fix walls and remove cracks is ACRYL-PUTZ® START. It does not show any shrinkage properties, dries fast, easy-to-grind. ACRYL-PUTZ® START putty mass is offered in loose form and thus must be prepared properly before use. Pour the estimated amount of ACRYL-PUTZ® START into a container with water, proportion around 1 kg of loose product for 0.3 litre of water and stir continuously.

Next stir carefully the content of the container with the help of a driller with a stirrer until obtaining a uniform, easy-to-apply mass.

ACRYL-PUTZ® START –Product preparation: stirring

It’s necessary to pay attention so that the prepared mass is stirred carefully and does not contain any lumps. The ready mass must be stirred again after 5 minutes and applied by using a putty knife made of stainless steel or plastic.

It’s important to clean the container/ bucket carefully before preparing the new mass. Mostly it’s recommended to apply the mass by using two metal putty knives made of stainless steel. The first narrow one is ideal to collect the mass from the container and put it upon the wider one. The second wide one is perfect to apply the mass upon the surface.

It’s also important so that the second spreading putty knife is always clean. All remains of the mass must be removed of the putty by using the smaller one. We always begin application from difficult-to-reach spots, a ceiling and next we smooth down flat surfaces of walls. ACRYL-PUTZ® START putty mass must be applied with single layers of 3 mm thickness. Thanks to it the layers dry fast and obtain an ideal smooth surface.

ACRYL-PUTZ® START –Applying the mass upon the wall

A cross-section of the wall with one layer

Smoothening – final layer

ACRYL-PUTZ® START has very low shrinkage properties, dries fast and thanks to specially selected compounds gives very smooth, white and easy-to-grind surfaces. Thus it can be used to perform the final levelling layer. The product particularly recommended for performing the final smoothening of walls is ACRYL-PUTZ® FINISZ. It is a high quality and ready-to-use putty mass which preserves a stable consistency during application and therefore can be used for a longer period of time. Excellent properties of the mass allow to apply it from 1 mm, which is particularly useful when performing additional adjustments upon the renovated surface. When not used and sealed it preserves properties for further use. ACRYL-PUTZ® FINISZ putty mass is ideal for machine application. Depending on the model of used machine, one must only dilute the mass by adding up to 5% of pure water. ACRYL-PUTZ® FINISZ must be applied with layers not exceeding 3 mm of thickness.

Applying the second layer of ACRYL-PUTZ® START or ACRYL-PUTZ® FINISZ

Machine application of the second layer - ACRYL-PUTZ® FINISZ)

Grinding the surfaces

Wall grinding

After drying it’s necessary to grind the surface by using a grip handle with sandpaper or abrasive net (gradation 100-150). Grinding sponge is especially recommended in corners and difficult-to-reach spots.

A cross-section of the wall with second layer

Inspection of performed smoothening

In order to carry out inspection of performed works one must direct the light (torch, lamp) parallel towards the wall. It will enable to notice possible roughness and badly grinded spots.

After grinding the surface must be carefully dedusted before applying the primer.

Smoothening inspection with the use of a torch

Surface preparation before painting

In order to level up absorptive properties and uniform the surface it’s recommended to apply before painting a latex emulsion primer for interiors – Sniezka GRUNT.

The product enhances efficiency of surface products, improves covering properties as well as provides a ventilation of walls.